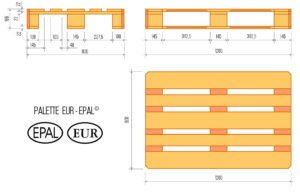

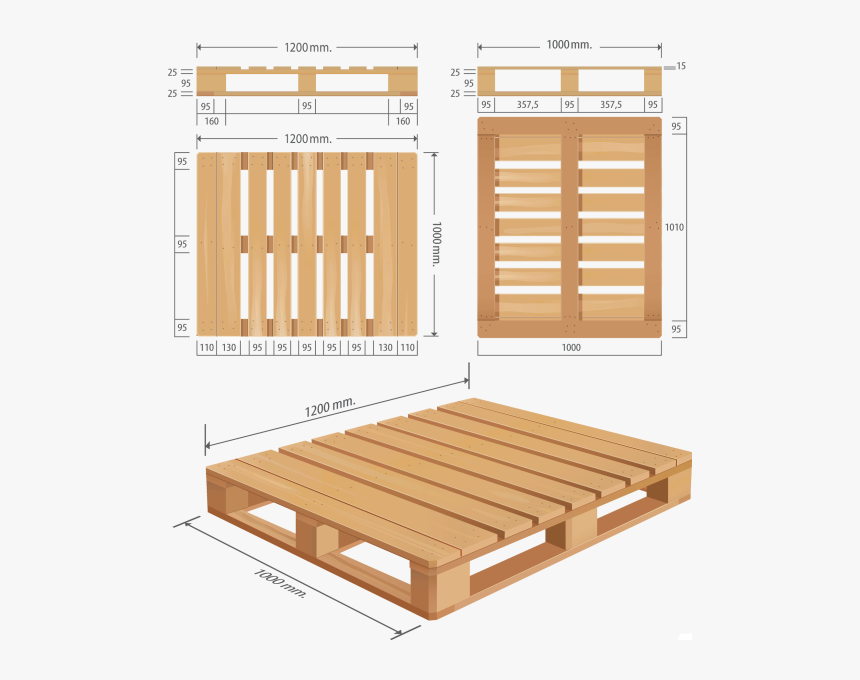

Accurate measurement is a vital aspect of logistics and transportation. It ensures that goods are transported efficiently, safely, and cost-effectively, regardless of the mode of transportation. Understanding the measurements of loading units used in the transport sector is crucial for logistics providers, shippers, and receivers alike.

At Logistitrade, we recognize the significance of using the right loading units and measurements to optimize the transport of goods. That’s why we have compiled a comprehensive list of measurements and specifications for commonly used loading units such as euro pallets, fin pallets, containers, and trailers. These measurements provide a standardized framework for logistics operations, allowing for seamless coordination between different stakeholders in the supply chain.

By understanding the measurements and capacities of each loading unit, shippers can better plan and optimize their cargo loads, while logistics providers can ensure the efficient use of space and resources. Accurate measurements also help to prevent damage to goods during transport and reduce costs by maximizing container utilization.

Whether you are a seasoned logistics professional or new to the industry, having a clear understanding of loading unit measurements and their relationship to various transport modes is critical. Browse through our slider to learn more about the dimensions and capacities of each loading unit and how they can be utilized to optimize your logistics operations.

40′ high cube container

40′ high cube container 45′ high cube container

45′ high cube container